Protecting the environment for future generations should be a top priority for all of us. But sometimes fact and fiction get blurred. Take printing, for example. It’s sometimes unfairly blamed for killing trees and other environmental damage. Not true. Modern printing can be very eco-friendly and print service providers make sure they run their companies sustainably. Here are some things you may not know about green printing.

At Bolger we are proud of our environmental commitments. We underwent a third-party certification audit and became one of the first commercial sheetfed printing companies in the United States certified as an SGP-certified printing facility. We passed environmental, health and safety, and energy audits, in addition to conducting indoor air quality tests.

Our efforts are ongoing and we publicly post our performance. We believe a company claiming sustainability as a core value should be tracking results. To see our latest results, click HERE.

Paper

Paper manufacturers are experimenting with paper production using easily renewable sources. Someday, we might see materials such as bamboo, eucalyptus, wheat, or straw as a common raw material, rather than traditional forests.

If wood fibers are harvested from traditional supplies, most printers adhere to certification programs that ensure their paper comes from sustainably managed forests. Popular certifications are the FSC (Forest Stewardship Council), Sustainable Forest Initiative (SFI), and PEFC (Programme for the Endorsement of Forest Certification).

All three programs track wood fibers through every step of the supply chain, from forest floor to print-shop floor, to make sure they meet standards for sustainable operations.

Eco-friendly paper is more affordable and available than ever, with many variations from which to choose. Many print projects use recycled paper, with 30% of fibers coming from post-consumer sources, pre-consumer-waste paper, or chlorine-free sheets.

And don’t forget that once paper materials have served their purpose, the fibers are recycled again.

Inks

Like paper, ink formulations have become easier on the planet. Latex ink, for example, unlike solvent or oil-based ink, is water based, odorless, and hazard-free. Its colorants dissolve from heat and adhere firmly to the substrate.

Eco solvent ink has a low volatile organic compound (VOC) content. Common VOC’s such as benzene, ethanol, and formaldehyde can evaporate into the air. Environmentally friendly inks require minimal ventilation and don’t clog ink nozzles. It’s scratch resistant, durable in most conditions, and can be used in many applications.

Biodegradable ink made from vegetable-based oil such as soya or rapeseed is even more bio-degradable, releases substantially lower volumes of VOCs, and renders paper easier to recycle.

Similarly, UV coatings used to produce impressive glossy surfaces are solvent free and fast drying.

Equipment

Print providers are adopting efficient control systems to maximize press efficiency. These systems help press operators set up presses to produce accurate color with fewer test sheets. Additionally, the equipment actually calculates how to print faster, and they manage the production process more efficiently. The result is savings in paper, water, inks, and energy, all of which create a smaller environmental footprint.

Digital prepress and production workflows function with paperless communication systems. A PDF file can move quickly from acceptance to the press. The organization reduces steps, cuts down on supplies, and lowers their energy consumption.

Gone too are the days of wasteful printing. Digital printing presses make it possible to print exact quantities as needed, in some cases reducing the need for inventory and reducing waste. They also do away with prepress equipment, traditional plates, and the chemicals used to process them.

Organizational

The printing industry is also adopting organizational measures to reduce its impact on the planet.

Chief among those measures is the Sustainable Green Printing Partnership (SGP), a third-party certification earned by printers that achieve acceptable performance in environmental evaluations. The certification process examines how printers reduce energy, implement health measures, and adhere to safety practices. SGP certifications also consider how printers reduce waste, including sending less trash to the landfill and recycling more paper and plastic. Measures printers take to lower emissions of greenhouse gases, limit water usage, recycle solvents, and other environmental metrics also factor into a firm’s qualifications for SGP certification. Bolger is one of only three SGP certified printers in Minnesota.

Qualifying for environmental certifications often includes retrofitting older buildings with upgrades, replacing lighting and inefficient HVAC units, capturing heat generated by machinery, and instituting recycling programs throughout the company. Business practice modifications can even extend to designing more efficient shipping logistics that use fewer boxes and better plotting of delivery routes.

An exciting new certification program called PrintReleaf plants trees based on an organization’s paper footprint. Bolger will be leading the way soon with this new initiative.

What About Digital Communications?

Many believe electronic documents and communication methods are less harmful to the environment because they do not consume paper. In truth, no form of communication is free of environmental impact. The environmental effects of digital communications include the consumption of energy every time a document is generated, transmitted, or read. In 2015, technology associated with information and communication consumed 3.6% of the world’s energy. The vast majority of that energy is generated by non-renewable resources like coal or natural gas.

Electronic communications also affect air quality and global warming. Measurements indicate that information/communications technology accounts for 1.4% of all carbon dioxide emissions.

E-waste is a term describing electronic gear that has reached the end of its useful life. According to the United Nations University, electronic gear accounted for 44.7 metric tons of e-waste in 2016. Only 20% of it was recycled.

Printing isn’t perfect, but the drive for ecological responsibility is ongoing and far-reaching. From order intake to the shipping dock, printing today is greener than ever.

Looking for a sustainable print partner? Contact us today!

"*" indicates required fields

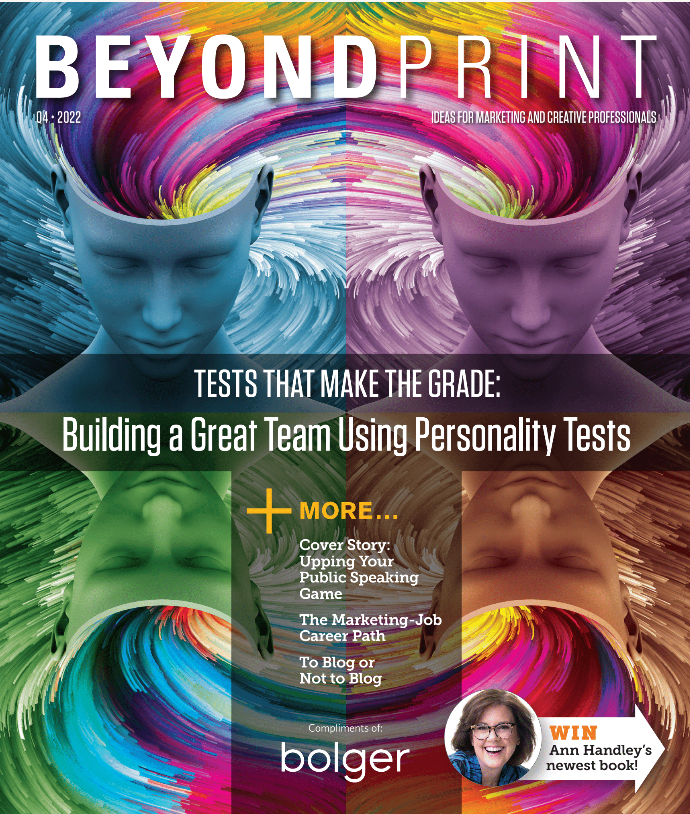

Beyond Print Magazine

Request your complimentary Beyond Print Magazine, mailed quarterly.